ما هي الرقائق الإلكترونية؟ العقل المدبر للعصر الرقمي

تُعد الرقائق الإلكترونية، أو ما يُعرف بالدوائر المتكاملة، بمثابة العقل المدبر الذي يحرك عالمنا الحديث. هي عبارة عن شرائح دقيقة مصنوعة بشكل أساسي من السيليكون النقي، تحتوي على مليارات من المكونات الإلكترونية الدقيقة تسمى الترانزستورات. تعمل هذه الرقائق كقلب نابض في كل جهاز نستخدمه تقريبًا، من الهواتف الذكية وأجهزة الحاسب الآلي، إلى السيارات والطائرات وأنظمة الذكاء الاصطناعي، حيث تقوم بمعالجة البيانات وتخزينها وتنفيذ الأوامر بسرعة فائقة.

خلفية تاريخية: ثورة غيرت وجه العالم

قبل ظهور الرقائق الإلكترونية، كانت الأجهزة الإلكترونية تعتمد على أنابيب مفرغة ضخمة وغير فعالة. لكن في أواخر الخمسينيات من القرن الماضي، أدى اختراع الدائرة المتكاملة بشكل مستقل من قبل جاك كيلبي وروبرت نويس إلى ثورة تقنية. سمح هذا الاختراع بدمج مكونات إلكترونية متعددة على شريحة واحدة صغيرة من مادة شبه موصلة. وقد مهد هذا الطريق لقانون “مور”، الذي تنبأ بمضاعفة عدد الترانزستورات على الرقاقة كل عامين تقريبًا، مما أدى إلى تسارع هائل في القوة الحاسوبية وتصغير حجم الأجهزة بشكل غير مسبوق.

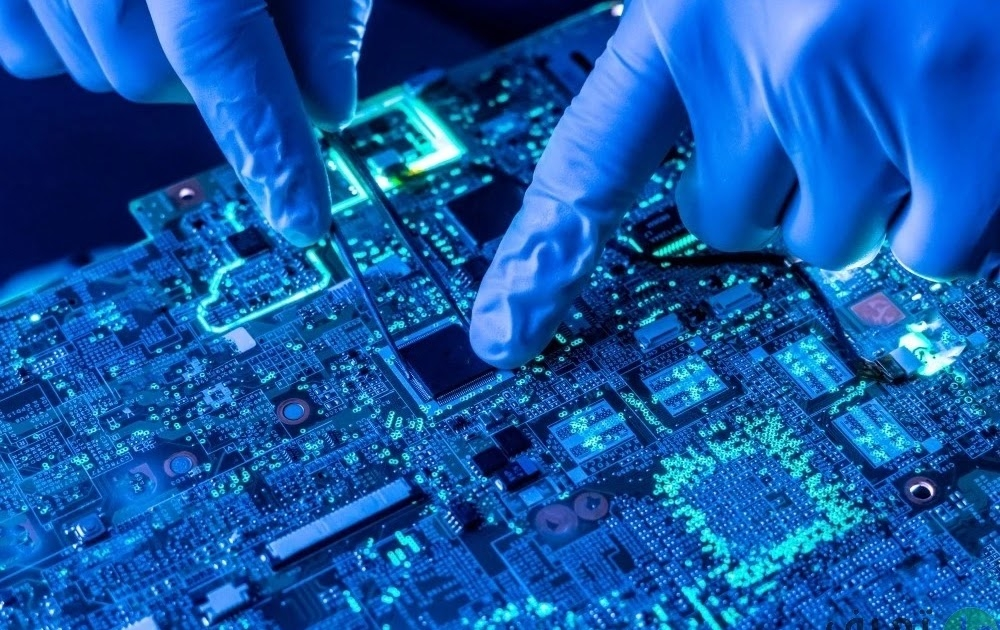

مكونات أساسية وعملية تصنيع معقدة

تعتمد صناعة الرقائق على ثلاثة أنواع رئيسية من المواد:

- أشباه الموصلات: العنصر الأهم هو السيليكون، الذي يتميز بقدرته على توصيل الكهرباء أو عزلها تحت ظروف معينة، مما يجعله مثالياً لصناعة الترانزستورات التي تعمل كمفاتيح كهربائية دقيقة.

- الموصلات: تستخدم مواد مثل النحاس والألمنيوم لإنشاء شبكة الأسلاك الدقيقة التي تربط بين مليارات الترانزستورات على الرقاقة.

- العوازل: مواد مثل ثاني أكسيد السيليكون تُستخدم لعزل الدوائر ومنع التداخل الكهربائي بينها.

تبدأ عملية التصنيع بسبيكة من السيليكون عالي النقاوة، تُقطع إلى رقائق دائرية رقيقة تسمى “ويفر”. بعد ذلك، تخضع هذه الرقائق لعملية معقدة للغاية تُعرف بالطباعة الحجرية الضوئية (Photolithography) داخل “غرف نقية” تخلو من أي جزيئات غبار. يتم خلال هذه العملية بناء طبقات متعددة من الدوائر الإلكترونية على الرقاقة بدقة متناهية تصل إلى بضعة نانومترات، وهي عملية قد تستغرق مئات الخطوات وتستمر لعدة أشهر.

الأهمية الاستراتيجية والحروب التكنولوجية

لم تعد الرقائق الإلكترونية مجرد سلعة تجارية، بل أصبحت أصلًا استراتيجيًا حاسمًا للأمن القومي والتنافس الاقتصادي العالمي. أدى تركّز صناعتها في عدد قليل من الدول، أبرزها تايوان وكوريا الجنوبية والولايات المتحدة، إلى خلق نقاط ضعف في سلاسل الإمداد العالمية، وهو ما تجلى بوضوح خلال جائحة كوفيد-19. هذا التركز الجغرافي هو السبب الرئيسي وراء ما يُعرف بـ “حرب الرقائق”، خاصة بين الولايات المتحدة والصين، حيث تسعى كل قوة لضمان تفوقها التكنولوجي والحد من وصول الخصم إلى أحدث التقنيات.

لماذا تعتبر الرقائق سلعة نادرة ومكلفة؟

يعود ارتفاع تكلفة الرقائق وندرتها النسبية إلى عدة عوامل متداخلة:

- تكلفة التصنيع الباهظة: يتطلب بناء مصنع واحد لتصنيع الرقائق المتقدمة (Fab) استثمارات تتجاوز 20 مليار دولار، بالإضافة إلى تكنولوجيا ومعدات فائقة التطور.

- الطلب العالمي المتزايد: مع انتشار إنترنت الأشياء، والذكاء الاصطناعي، والسيارات الكهربائية، يتزايد الطلب على الرقائق بشكل يفوق قدرة الإنتاج الحالية.

- الاعتماد على مواد نادرة: يدخل في تصنيعها عناصر أرضية نادرة ومعادن حيوية مثل الكوبالت، والغاليوم، والتنتالوم، والتي تتركز مصادرها في مناطق جغرافية محدودة، مما يضيف بعدًا جيوسياسيًا لتوفرها.

جهود المملكة في توطين صناعة أشباه الموصلات

إدراكًا لهذه الأهمية الاستراتيجية، تسعى المملكة العربية السعودية، ضمن رؤية 2030، إلى توطين التقنيات المتقدمة وبناء اقتصاد قائم على المعرفة. وفي هذا السياق، أعلنت مدينة الملك عبد العزيز للعلوم والتقنية “كاكست” عن نجاحها في تصميم وتصنيع 25 رقاقة إلكترونية متقدمة بأيدٍ سعودية. هذا الإنجاز، الذي تم بالتعاون مع باحثين وطلاب من جامعات سعودية، يمثل خطوة تأسيسية هامة ضمن البرنامج السعودي لأشباه الموصلات، ويهدف إلى تأهيل الكوادر الوطنية ودعم منظومة البحث والتطوير في هذا المجال الحيوي لتطبيقات متعددة تشمل الاتصالات وأنظمة الاستشعار والطاقة.